PRODUCTION FACILITY

PREPRESS

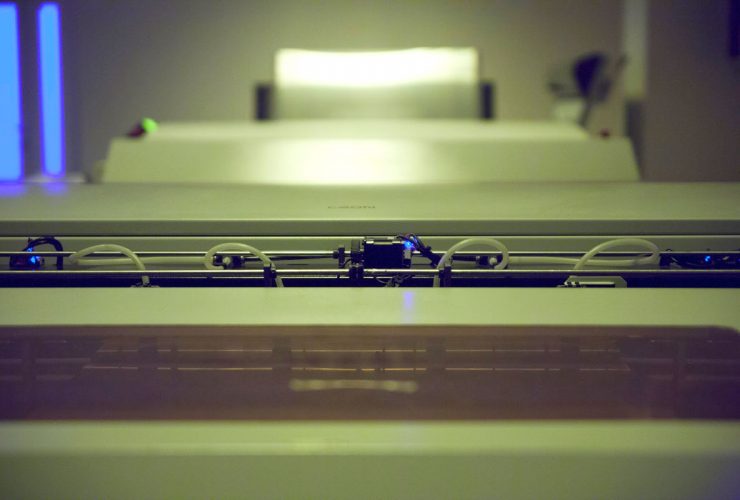

A CtP system – CRON UVP 4696GX thermal platesetter and Glunz & Jensen HDX thermal plate processing machine

EPSON STYLUS PRO 4900 printer

IMAF developer

Lüscher XPose!, thermal platesetter, B1 format

Printing house

Heidelberg Speedmaster SM-102-4-P

Heidelberg Speedmaster CD 102-5

Zirkons

Heidelberg CD 74-5 LX

Heidelberg Speedmaster SX 102 8-P

Binding

Valore Müller Martini

Acoro A5 Müller Martini

Hardcover

Folding machines

Finishing

Heidelberg Cylinder SBG

IT tools

SISTRADE – calculation and planning software

PRINECT – CIP3 SYSTEM