Education Through Passion – Opolgraf Inspires Future Generations of Book Lovers

At Opolgraf S.A., we believe that knowledge, curiosity, and a connection with books help shape the future. That’s why we’ve been actively engaged in educational initiatives for many years, reaching out to people of all ages – from preschool children to teenagers and adults. Our printing house regularly opens its doors to those who want to discover, up close, how a book is truly made – from concept to finished product.

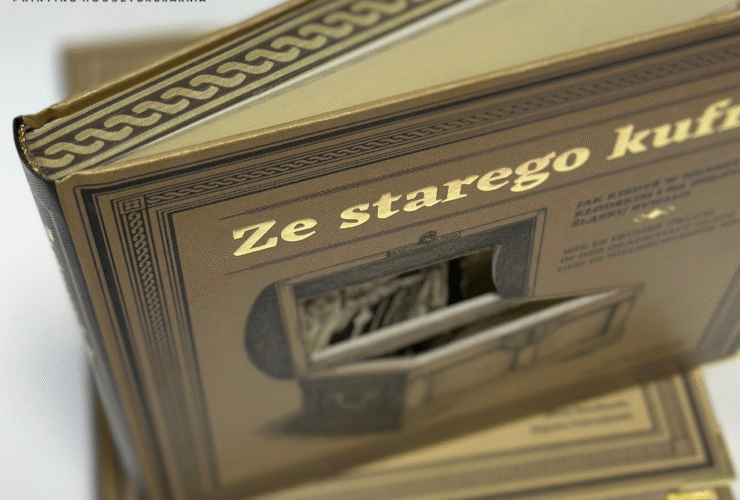

During specially organized educational visits, participants are guided through each stage of book production: from design and prepress preparation, through printing, to binding and finishing. We demonstrate how modern printing technology works, while also highlighting the precision, craftsmanship, and teamwork required to produce every publication.

A key part of our educational efforts involves hosting the youngest visitors – preschoolers and primary school students. In an accessible and engaging way, we introduce them to the fascinating world of books, encouraging reading and the development of creative interests. Children not only get to see what a professional printing house looks like “from the inside,” but also learn that behind every book lies the work of many people – editors, designers, printers, and bookbinders.

Our educational initiatives are not only a way to promote the printing industry, but above all, a way to share our passion for books and print. We believe that hands-on experience with the book creation process can inspire curiosity, instill respect for craftsmanship, and spark lifelong interests.